- Who We Are

TVS Training and Services (TVSTS) offers customized training programs tailored for industrial personnel across diverse sectors. These programs focus on delivering domain-specific knowledge, technical skills, and essential social competencies.

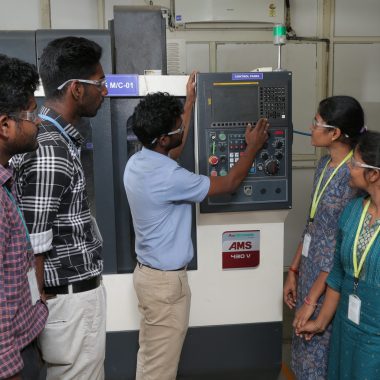

Our B2B training programs are flexible and can be conducted either face-to-face or online, based on the specific needs of our clients—except for hands-on training, which requires in-person sessions. Face-to-face training takes place in our state-of-the-art labs at the TVSTS training centre, providing an immersive learning environment.

All B2B programs are led by our highly skilled in-house trainers, who bring years of robust industry experience and collaborate closely with subject matter experts from various sectors. Their expertise ensures that the training is both relevant and practical.

TVSTS proudly serves a broad spectrum of industries, including Automotive, Engineering, Energy, FMCG, Pharmaceuticals, Electronics, and Healthcare, delivering tailored solutions that meet the unique demands of each field.

Our B2B training programs are specifically designed to equip personnel for shop floor roles, closely aligned with real-time job requirements in the industry. These programs have been developed in collaboration with leading industry and academic experts to ensure relevance and effectiveness.

We also provide specialized induction training tailored for graduate engineering students entering the workforce. Certification for material handling programs is provided by LSE, while all other programs are certified by TVSTS, ensuring recognized standards of quality and competency.